To be a distributor

Ask a question

Make an enquiry

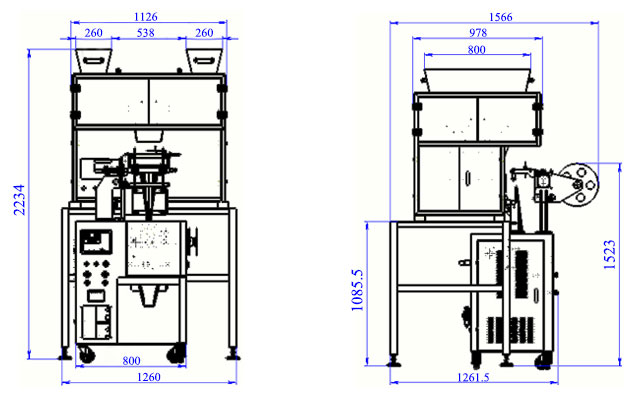

HiTec pyramid tea bag packing machine offers a variety of weighing systems with top precision, ideally suited to long-leaf tea, herbs as well as any premium tea(such as black tea, green tea, flower tea, loose tea, blending tea, etc). Responding to the market trends, it can process both pyramid tea bags and tetrahedral tea bags with or without string and label, moreover, it can be combined with other equipment like outer envelope, cartoning unit,etc. it's versatility allows packaging according to market demand.

GET A PRICE/QUOTE

ASK A QUESTION

RECEIVE DOCUMENTATION

Pyramid tea bag with string and label

Pyramid tea bag without string and label

Rectangular tea bag with string and label

Rectangular tea bag without string and label

The Benefits

Ultrasonic sealing & cutting technology produce neat and beautiful tea bag.

Guarantees energy saving.

Allows to use sustainable packing material for a complete eco-friendly packaging.

Top precision dosing weighing system.

Easy to convert from pyramid tea bag to rectangular tea bag through one button.

Feature a variety of product infeed options depends on different packaging applications.

Hygienic design, each part in contact with material is food-grade.

High productivity reaches up to 120 bags/min.

Convenient to replace and maintain.

Rapid cleaning of doser, reduced changeover times from one product to another.

Two-way eye mark detecting, precise positioning.

Selectable sealing times once or twice for completely sealing.

Comply the CE standard, meets the needs of customers who have the CE requirements.

| Model | HiTec-LST | HiTec-MST | HiTec-HST |

| Capacity | 40 bags/min | 60 bags/min | 80-120 bags/min |

| Measurement | Standard: multihead weighing system Option: linear, volumetric cup, auger filler | ||

| Packing material | Nylon mesh/PLA/PET/Non woven(suitable for ultrasonic sealing) | ||

| Film width | 120mm, 140mm, 160mm, 180mm | ||

| Bag type | Pyramid / Rectangular tea bag | ||

| Compressed air | 280L/min. (6 bar) | ||

| Power | 1-P, 220VAC, 50/60Hz, 2.5KW | ||

| Weight | 400kg | 420kg | 480kg |

--Collar format for different bag size.

--Weighing system(linear, volumetric cup, auger etc...)

--Finished product conveyor belt.

--Z type elevator(automatic tea feeding).

The process cycle of tea bag has been specially designed by engineers with precise aim of following each single action or production step, begining with the use of individual packaging material reels such as tag, filter material, as well as cotton thread, resulting in a very easy accessible linear structure. From the forming of filter bag material tube complete with tag and cotton thread and passing through the first vertical sealing & cutting station, a subsequent filling once, then, through the second horizontal sealing & cutting, finally each filter bag takes shape step by step and ready to be processed in the next packaging station such as overwrapping or cartoning, each single move is controlled through the PLC.

HiTec pyramid tea bag packing machine adopts ultrasonic sealing and cutting technology, compared with traditional heat-sealing system, it has the advantage of energy saving, no use of expensive packing materials, you can even able to run regular nylon mesh roll, non-woven, paper tag and cotton thread, significant savings, in addition, machine equips with two-way sensor which detect defects of tag on the filter, automatic recognition and tracking, thus minimizing down time. Responding to the latest market trends, it allows the use of biodegradable materials for a complete eco-friendly package. For the different tea packaging applications, except for the standard multihead vibrating weighing system, HiTec engineers have designed optional volumetric cup, auger, linear, etc for you as well.

Headquarter:

Manufacturing plant:

Become a Distributor

Learn how to become a representative of HiTec in your region / country

Ask a Question

Ask a Question

Get a price/Quote

DOWNLOAD FORM