To be a distributor

Ask a question

Make an enquiry

Every premade pouch filling sealing machine from HiTec is custom made according clients' demands, it's capable of running a variety of pouch types within it's pouch size range, easy integration with volumetric cup filler, multi-head weigher, auger, liquid pump, as well as infeed and outfeed conveying equipment. Two extra stations can also be added for more capabilities and features beside standard ones.

GET A PRICE/QUOTE

ASK A QUESTION

RECEIVE DOCUMENTATION

Doy bag

Doy bag with zipper

Doy bag with hole

Stand up pouch

The Benefits

Compact overall footprint

30-Second changeover

Centralized adjustments for gripper width

Wide pouch size range

High flexibility

SS 304 steel machine frame

Supports multiple bag types

Nitrogen gas flushing before sealing, keep product fresh

Various infeeds, such as auger, multihead weigher/scale, volumetric cup

Applicable in almost any industry(Food, Confectionery, Home care, Pet food, Pharma, Personal care)

| Model | HiTec-APM | HiTec-PPM | HiTec-MPM |

| Capacity | 10-40 bags/min | ||

| Filling range | 1-2000Grams(depends on the density of the raw material) | ||

| Measurement | Auger | Pump | Multihead weigher |

| Precision | ±0.2-3Grams(depends on the material) | ||

| Bag size | 120-380 * 100-260mm(Length * Width) | ||

| Bag type | Stand up pouch, Zipper bag, Sitting bottom bag, Gusset bag, Doy bag | ||

| Packing material | PP, PE, PVC, PS, EVA, PET, PVDC+PVC, OPP+Composite CPP etc | ||

| Power | 380VAC, 50/60Hz, 3.8KW | ||

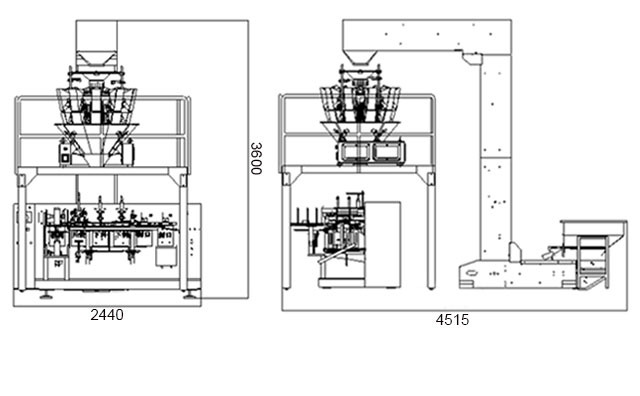

| Dimension | 2440 * 1480 * 2380mm | 2540 * 1480 * 2080mm | 4515 * 2440 * 3600mm |

--Measurement(auger filler, multi-head electronic scale).

--Zipper option.

--Date code printer.

HiTec's Pre-made pouch fill and seal machine include an easily accessible bag magazine( to ensure every bag enters the machine operation), an automatic zipper opening device, a filling station with bag shaker, and an integrated finished product exit conveyor. It feature a variety of options depending of your packaging needs, can pack almost everything into a pouch. The straight-line design, horizontally loading product, creates a distinct apperance and ensures the operator can see the entire bag opening, filling and sealing processes without the assistance of others, makes it easier to operate, service and clean. It's engineered for medium to high production rates up to 2,400 bags per hour.

It's capable of running a variety of pouch types, such as doy bag with or without zipper, pillow pouches, 3-side or 4-side seal pouches, stand-up pouches(SUP, SURP, DOY), and handling a wide range of pouch sizes. As the pouches are already made, so the usage of premade bags also reduced the level of expertise needed to operate a machine, even an new employee can manage the infeed of bags and collection of filled pouches with relatively little training.

Headquarter:

Manufacturing plant:

Become a Distributor

Learn how to become a representative of HiTec in your region / country

Ask a Question

Ask a Question

Get a price/Quote

DOWNLOAD FORM