To be a distributor

Ask a question

Make an enquiry

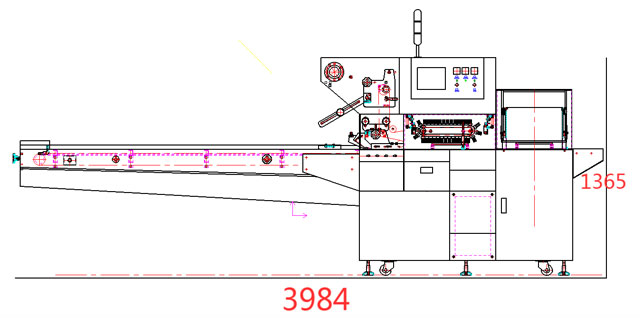

HiTex-S series horizontal flow wrap machine is an entry-level wrapper that ideal for small and mid-sized enterprises, it's suited to wrapping both food and non-food products, each model is available in different configurations with an extensive range of optional add-on modules. HiTec flow wrappers can be tailored to match each customer's specific needs and delivery maximum production flexibility and efficiency at each performance level.

GET A PRICE/QUOTE

ASK A QUESTION

RECEIVE DOCUMENTATION

Pillow bag with gusset

Pillow sealing bag

Zig-zag cut pillow bag

Bread or bakery in thermoforming

The Benefits

High flexibility with maximum productivity.

Offers wider product size range, suitable for nearly any industry, such as bakery, bars, biscuits, cookies, and crackers, fresh produce, medical devices and more.

Fast heat sealing and very tight seals.

Hygienic design, easy to operate, clean and maintain.

Nitrogen gas filling device(optional).

Flat cut, Zig-zag cut or clip cut-off.

Easy set-up, fast changeover, reduce product and film waste during production.

Flexible design can handle a wide range of products.

Fast delivery, quick parts and service response.

Low maintenance costs.

Superior seal integrity and package quality.

HiTec horizontal flow wrappers mainly perform three tasks in the continuous operation-bag forming, product filling, as well as sealing and discharging the finished package. During the horizontal wrapping process, the product is placed on the flat chain conveyor belt through manual or automatic sorting system, where it travels horizontally to the sealing head, then, a heat-sealable film is wrapped around the product, sealed and cut. All of these processes are completed automatically by the same machine, the result is a protective, consistent and professional looking package. It can be combined with other equipment like cartoning machines, cardboard dispenser, as well as track and trace systems for seamless traceablity of the packaged products. Horizontal flow wrappers can be used for a wide range of products and applications, such as delicate products, single-serve goods, products in trays(cleaning wipes, cookies, pastries, desserts, napkins, pre-wrapped plastic cutlery, etc.), even medical devices and industrial parts. Based on the desired output volume, HiTec flowpack machines provide optional automatic splicing device, the film reel can either be changed manually or with the help of splicer once it run out, it can fully connects the old and new film to avoid disturbances at the film former.

| Model | HiTec-S250 | HiTec-S450 | HiTec-S600 |

| Capacity | 20-80 bags / min | 40-230 bags / min | 40-230 bags / min |

| Film width | 450 / 600mm | 250 / 350/ 450mm | 350-800mm |

| Bag length | 120-450mm | 65-190/120-280mm | 65-420mm |

| Bag width | 50-200/50-280mm | 30-210mm | 50-210mm |

| Height | 10-120mm | 40-70mm | Max.60mm |

| Roll diameter | Max.320mm | Max.320mm | Max.320mm |

| Power | 220V 50/60Hz/3.2KW | 220V 50/60Hz/2.8KW | 220V 50/60Hz/2.6KW |

| Weight | 960-1160KG | 800-980KG | 700-920KG |

| Dimensions | 4380 *970 *1500mm | 4120 * 820 *1320mm | 3984 *800 *1365mm |

-Automatic reel splicer

Headquarter:

Manufacturing plant:

Become a Distributor

Learn how to become a representative of HiTec in your region / country

Ask a Question

Ask a Question

Get a price/Quote

DOWNLOAD FORM