To be a distributor

Ask a question

Make an enquiry

Heat tunnel shrink wrapping is one of the most widely used packaging methods, due to it's aesthetics and practicality. The continues pace allows for faster pack times and in-feed systems make sure the right amount of shrink film is applied. Unlike the models with L-Sealer, these series use a side sealing wheel finishes the final seal to enclose the product, with the ability to wrap longer products, a perfect option for shrinking wrapping moulding, pipes, wood, and other elongated items.

GET A PRICE/QUOTE

ASK A QUESTION

RECEIVE DOCUMENTATION

The Benefits

Sealing knife with stable temperature control, power saving and easy change.

Simple design, easy operation.

Imported photoelectric detection, optional vertical detection, easy to convert.

Automatically compensates for package length change.

Strong seal and nice look.

Film saving and high efficiency .

Functional, innovative and elegant design.

Adapted to a variety of shrink films.

Super flexibility to wrap a wide range of products, shapes and size.

Stronger than alternative wrapping solutions like overwraps or stretch wraps.

| Model | HiTec-B550 |

| Capacity | 15-30 bags/min |

| Package size | Length: Tailored Width: <400mm |

| Shrink tunnel | 800 * 400 * 200mm |

| Product size | 400 * 200mm(W * H) |

| Conveying speed | 0-15 meters/min |

| Conveyor type | Mesh belt, Roller chain, Teflon |

| Conveying weight | Max. 10KG |

| Shrink film | POF, PVC, PE |

| Compressed air | 0.5-0.7Mpa |

| Power | Cutting & Sealing: 220VAC, 1-Phase, 50/60Hz,1.35KW Shrink tunnel: 220-380VAC, 3-Phase, 50/60Hz, 5.5KW |

| Weight | Cutting & Sealing: 300KG Tunnel: 45KG |

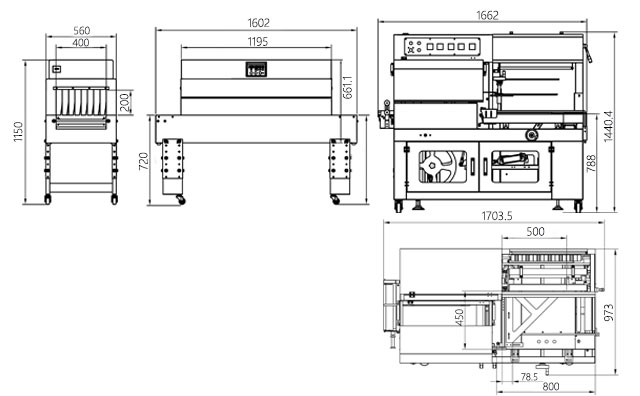

| Dimensions | Cutting& sealing: 1650 * 800 * 1450mm Shrink tunnel: 1100 * 800 * 300mm |

Side seal shrink wrap machine is high speed continuous motion shrink packagers, with a variety of shrink film options and in-feed systems these shrink wrap machines are perfect for packaging solutions that package a variety of products. It uses a photo eye to detect products as they pass through on the conveyor, after products pass, a single-sealing arm running perpendicular to the film closes behind the product. The width of the product is limited to the vertical sealing bar, but length can be as long as needed, the packaging height is adjustable based on product as well.

The heat shrink film is made of polypropylene and polyethylene: bright, soft and versatile, glossy and trasparent, resistant and eco-friendly, different reels are available, if the film is properly applied by a shrink wrap machine then the packaging will conform more tightly to the product shape.

Headquarter:

Manufacturing plant:

Become a Distributor

Learn how to become a representative of HiTec in your region / country

Ask a Question

Ask a Question

Get a price/Quote

DOWNLOAD FORM